Leviat’s MB Super Lynk replaces traditional panel-to-foundation connections with a simple, bolted solution - reducing labor costs and streamlining installation without compromising structural integrity.

Tilt-up construction involves the lifting and placement of concrete panels often multiple stories in height and well over 50,000 tons in weight. The connections between these massive elements and the footings they rest upon provide critical stability for the building envelope while it is under construction as well as the permanent tie between the walls and the foundation.

Traditional Connections

Historically, contractors have relied on embedded weld plates in the panel and the slab to connect the two. While usually effective, this method presents several challenges that can hinder project efficiency and increase costs:

- Welded connections require certified welders to be present on-site, which not only raises labor expenses but also introduces additional scheduling and safety complexities.

- The process itself is time-consuming and can be significantly delayed by adverse weather conditions, making it impractical in many scenarios.

Another connection commonly used is a grout sleeve system, which ties the panel reinforcing to the foundation rebar using embedded couplers. To make those connections, contractors face a host of possible hurdles:

- Care must be taken to install the couplers in precisely the correct location to be able to accept the rebar from the footings

- The footing reinforcement must remain exposed along the perimeter for weeks or even months after its casting. This creates a significant safety hazard, as well as an increased possibility of damage to those reinforcing bars.

- Panels must remain braced for at least one day for the grout to gain enough strength to make the connection

- Grout systems typically cannot be used when temperatures are expected to remain below 40 F

One shared shortcoming between weld plates and grout sleaves: repairs and fixes for all-to-common installation misalignments are time-consuming and costly.

Super Lynk Benefits

Leviat’s MB Super Lynk solves these traditional issues using a bolted connection system that simplifies installation and reduces labor costs. Super Lynk’s pivoting connection plate allows installers to adjust the final bolt location to avoid rebar in the slab, giving it flexibility that splicing systems or welded connection don’t have.

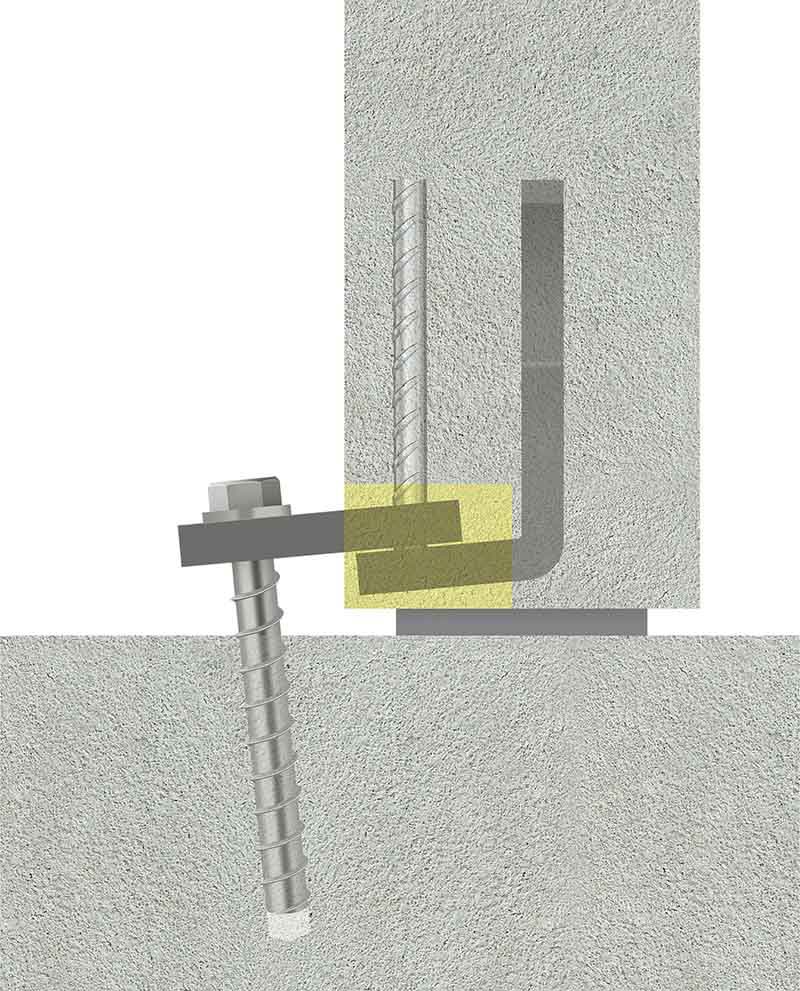

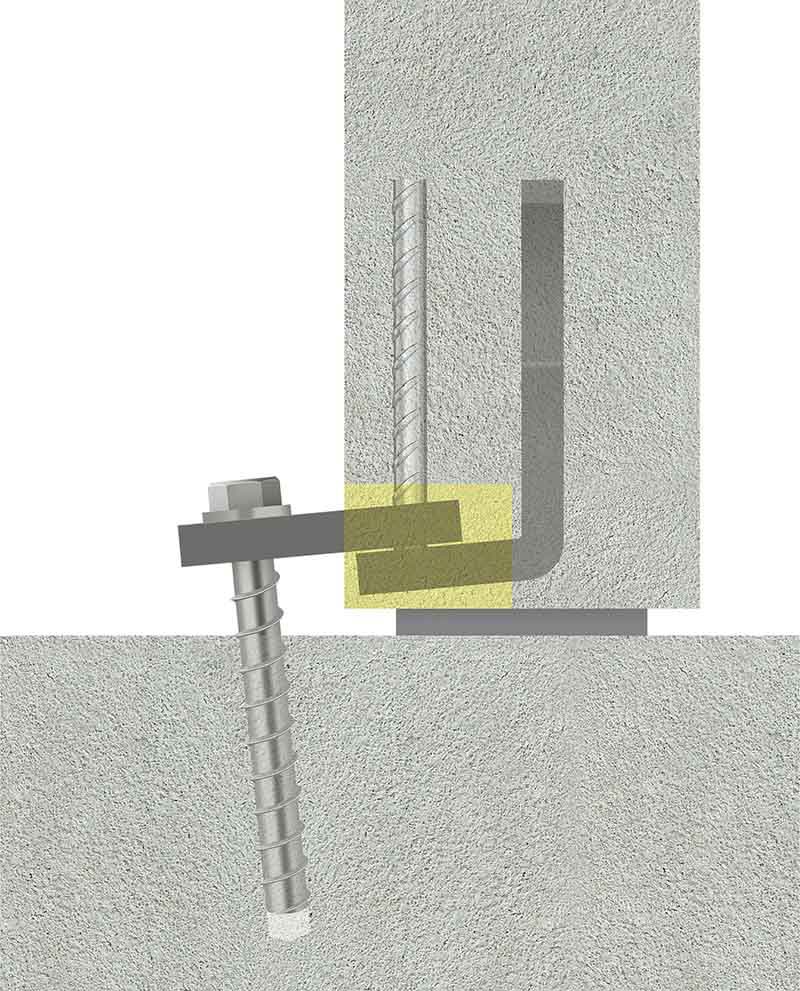

Figure 1: Super Lynk is installed in the panel and bolts to the foundation.

Figure 2: Super Lynk is easily installed with just two screws into the form.

Figure 3: To complete the connections, contractors simply remove the void cap, swivel the link into place, drill a pilot hole, and drive the bolt into the footing.

Unlike welded systems, Super Lynk can be installed quickly and easily using general labor, eliminating the need for specialized trades. This shift not only streamlines the construction process but also makes it more adaptable to varying site conditions.

Fast, Easy Installation

In several times studies, Super Lynk connections took just under two minutes each to complete. When factoring in equipment movement and other factors, the welded connections each took almost 15 minutes to finish. This adds up to significant reduction in safety concerns overall labor costs when considering the hundreds of such connections on a typical tilt-up project.

Each Super Lynk unit integrates smoothly into formwork and requires minimal void dimensions - just under 2½ inches in profile - ensuring that it can be easily concealed within standard grout lines and landscaping.

While Leviat’s standard MB Super Lynk does not provide shear capacity, it meets the tie requirements outlined in ACI 318-14 Section 16.2.4.3(b), offering a tension capacity of 10,000 pounds when used with 2,500 psi concrete.

Shear connections are typically not required for tilt-up panel connections, although this determination should always be confirmed by the project’s Engineer of Record. In those special cases where a shear connection is required, the MB Super Lynk SR offers shear capacity up to 7,000 lbs using a locking connection plate.

In short, Leviat’s MB Super Lynk system represents an innovative, strong, and discreet solution for permanent panel-to-foundation connections in tilt-up construction. By addressing the limitations of welded connections and offering a fast, cost-effective, and adaptable solution, it empowers construction teams to work more efficiently without compromising structural integrity.